What is pyrolysis?

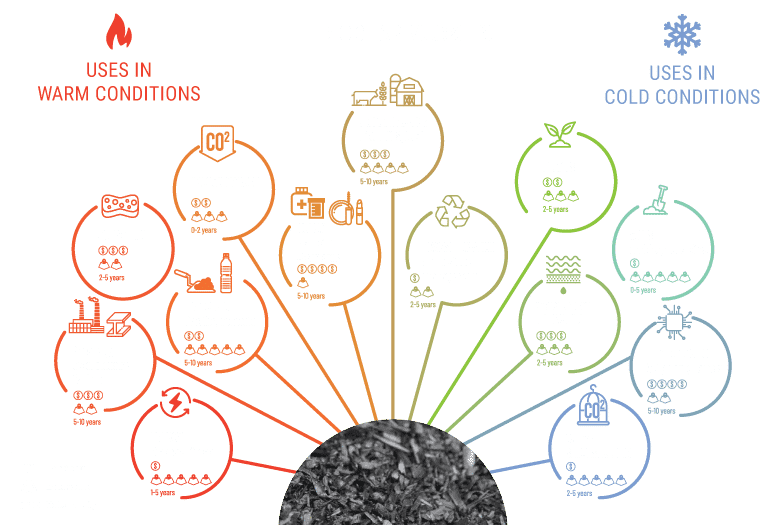

Pyrolysis is the thermal decomposition of carbonaceous materials in an oxygen-free environment at high temperatures, between 300 and 900 ° C. Pyrolysis can turn any biomasses, tires and even plastics into renewable products. The pyrolysis process is not the same as that of combustion or incineration. In fact, it is much more environmental. The technologies are extremely varied, as much in terms of input, size and products as in pricing.

Pyrolysis products have several markets. They can be used in the circular and green economy, but also in more traditional markets and industries, such as the energy sector.

Environmental benefits of pyrolysis

Climate change is not a myth: let’s act now using pyrolysis!

Greenhouse gases (GHGs) like CO2, CH4 and N2O accelerate climate change. Methane (CH4) has a global warming potential 25 times that of CO2. CH4 emissions from combustion and landfilling of residues and livestock production account for up to 19% of global CH4 emissions. In addition, the in situ decomposition of residues and waste releases large amounts of CO2 and CH4 which cannot be recycled. Pyrolysis of residues destined for landfill or unmanaged can offset up to 4 tonnes of CO2 equivalent per tonne of waste. Pyrolysis therefore stands out as a very effective solution to generate value-added products from residues. Through the environmental usage of these pyrolytic products, we can reduce our contribution to climate change, as well as the contamination of soil, water and air.

In addition, pyrolysis is a complementary technology to other technologies. For example, it is possible to use pyrolysis to heat anaerobic digestion plants, transform non-recyclable plastics and create biochar to improve the compost.

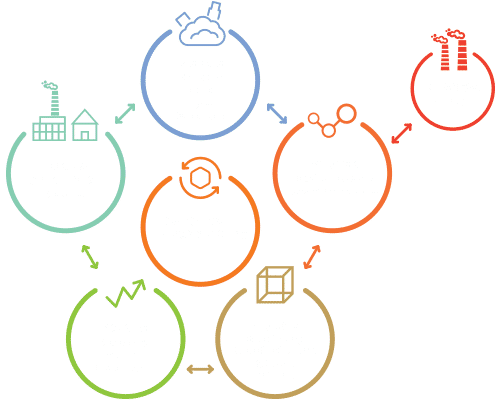

What is biochar or char?

Char and biochar are black materials that contain a lot of carbon. The term biochar usually refers to char created from virgin material, while the term char can be used for a product made from contaminated wood or sludge. These chars and biochars look like coal. In fact, charcoal is a type of biochar. Biochars can describe different products, depending on their properties and uses. They are light and very porous. They can sorb contaminants, nutrients, water, gases and odors, and can also be used for carbon sequestration, to replace fossil coal, as an additive for materials like concrete and plastic, in food, in agriculture, environment and pharmaceuticals. The properties of each char and biochar depend on a combination of the pyrolyzed materials, the technology used, the temperature, the residence time during processing as well as the conditionning. These combinations create a unique product.

Environmental benefits of char and biochar

Biochar, a catalyst in the green economy

The production of biochar helps prevent air, water and soil contamination by residues. In addition, some biochar can be used to filter water and air, while others are used to decontaminate soils or reduce the need for fertilizers and pesticides. They can also help reduce GHG emissions in a number of ways. Among other things, biochar can limit or reduce emissions when it is added to cattle feed, in manure and slurry pits, sequestered or used as a replacement for fossil charcoal, to name a few. In fact, biochar can sequester up to more than 3 tons of CO2 per ton of non-combusted biochar.

What is wood vinegar?

Wood vinegar, also called pyroligneous acid, is the aqueous phase of the condensed liquid collected from the pyrolysis of biomass. The condensed liquid, often referred to as “oil”, contains 15-60% water and water-soluble molecules, while the other part of the liquid, the organic phase, contains oil as well as organic molecules. The water concentration in pyrolytic oil depends on several factors, including the pyrolyzed material and its initial water concentration. Wood vinegar can be extracted from oil by any of the following methods or a combination of these: distillation, osmosis, centrifugation and decantation. Wood vinegar contains over 100 chemicals, but is usually made up primarily of water, acetic acid (0.1-10%), and several phenols.

Waste Management and Transformation

Leveraging wastes to produce renewable products and energy can be profitable!

Avoiding landfills with pyrolysis

Landfilling takes up a lot of space, emits odours as well as greenhouse gases, and pollutes water even when the site is well designed (Xiang et al. 2019). Both transportation and act of landfilling itself generate huge amounts of GHGs from fossil fuels used in machinery. It is important to note that the wastes that are simply left in the wild are even more polluting and cause problems to the flora and fauna. All types of carbonaceous materials (eg. contaminated biomass, tires, plastic), otherwise sent to landfills, can be pyrolyzed to create renewable products or green energy. Obviously, the products and their ratio depend on several factors.

From residues to clean products

In addition to reducing GHG emissions, all biomasses that are contaminated with organics (ex: rail road ties) could be cleaned with pyrolysis or gasification technologies. The organic molecules are broken down into smaller ones such as CO, CO2, oil and more. The solid material (char) can then be used for most of the applications listed above. The liquids can be used as renewable fuels or for chemical extracts. Thus, a whole new series of renewable products, in addition to renewable energy, can be produced from wastes and “non-recyclable wastes” such as contaminated cardboard and plastics

Energy from wastes

Transforming local residues into energy through pyrolysis or gasification limits pollution, decreases transport costs and time, creates jobs and reduces the environmental impacts associated with their extraction (eg mining). Obviously, residues can come from sources such as landfills, compost waste, construction materials, etc. It is also possible to use contaminated feedstocks, since the majority of contaminants can be extracted, as long as they are not heavy metals. Since cities and businesses know the costs of cleaning up or soil, water and air decontamination, as well as landfill costs, the social and economic impacts of pyrolysis become evident.